Aluminium foil is manufactured by a process of foil-rolling and annealing from cold-rolled coils to target thicknesses under 0.20mm followed by tempering. Aluminium foil products are closely related to people’s daily necessities.

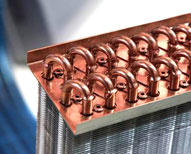

Aluminium foil has excellent heat-absorption and radiation properties, making it the major material, especially as fin-stock, for heat-exchangers in air conditioners and refrigerators. Coating treatment used to be carried out after heat exchangers had been assembled. To protect the environment, advanced aluminium factories around the global have put in a tremendous effort to develop pre-coated fin-stock. CSAC has also invested in R&D and established pre-coating fin-stock production lines in order to supply highly-efficient products to its customers.

With its excellent shielding characteristics from electro-magnetic waves, aluminium foil is widely used as a shielding material for cables and electronic components. Furthermore, after lamination with other materials, it becomes a main material for various kinds of packaging, such as laminated foil for food packaging, Tetra Pak containers, candy wrappings, can seals, beverage packaging, and other consuming product packaging because it provides protection from sunlight to maintain the freshness of a product and suitability for printing.

Fin stock for Heat Exchangers

| Alloys | Si | Fe | Mn | Mg | Cr | Zn | Ti | Others | Al | |

| Each | Total | |||||||||

| 1100 | Si+Fe 1.0 max. |

0.05 - 0.20 | 0.05 max. | 0.10 max. | 0.10 max. | 0.06 max. | 0.05 max. | 0.15 max | 99.00 min. | |

| 1200 | Si+Fe 1.0 max. | 0.05 - 0.20 | 0.05 max. | - | 0.10 max. | 0.05 max. | 0.05 max. | 0.15 max | 99.00 min. | |

| 1300 | 0.2 max. | 0..4 max | 0.10 max | 0.40 max. | 0.05 max. | 0.05 max. | 0.17 | 0.05 max. | - | 99.00 min. |

| 3102 | 0.2 max. | 0..4 max | 0.10 max | 0.05 - 0.40 | 0.05 max. | 0.05 max. | 0.10 | 0.05 max. | - | 99.00 min. |

| Thickness & Tolerance(mm) | Width & Tolerance(mm) | Core I.D.(mm) | Max. Coil O.D.(mm) |

| 0.10-0.30 (±5%) | 100-1000 (±0.5) | 150、200、305 (Paper、Steel or Al.Core) |

1000 |

| 1000-1250 (±1.0) |

| Alloys | Temper | TS(N/mm2) | EL(%) |

| 1100 | O H22 H24 |

80 - 110 | 15 min. |

| 100 - 135 | 15 min. | ||

| 110 - 150 | 8 min. | ||

| 1200 | H22 | 95 - 130 | 15 min. |

| 1300 | H26 | 125 - 160 | 4 min. |

| 3102 | H26 | 120 - 160 | 4 min. |